Reasons of failures

Main reasons of turbochargers' failures

1. Damage by strange material

Dented and bent blades of compression or turbine gears are caused by the foreign bodies entering the suction or exhaust ducts. Before replacing the turbocharger the patency and cleanliness of engine’s suction and exhaust installation have to be checked.

Do not straighten the blades by yourself!!!

The rotation assembly has to be dynamically balanced !!!

Possible reasons:

• broken parts of engine,

• fractured parts of connections or other objects that made their way inside;

• bolts/nuts/sand/stones/hard objects left in the charging air installation.

|  |  |

2. Dirty oil

Polluted oil causes deep grooves on turbocharger’s bearings. In order to prevent such damages the oil and filters of good quality should be replaced according to the maker’s guidelines.

Possible reasons:

• blocked, broken or poor quality oil filter;

• excessive wear of the engine (broken parts);

• failure of the oil filter overflow valve;

• poor quality of engine oil;

• too long time gap between oil replacements.

3. Irregularities in oil supply

Irregular (4-5 seconds breaks) in oil supply lead to polishing and scorching surfaces of bearings’ sleeves.

Possible reasons:

• turbocharger replacement without filling with oil;

• replacement of oil and oil filter;

• long period of the vehicle being unused;

• incorrect starting of the engine after turbocharger replacement or repair;

• inadequate oil pressure du to lubricating installation malfunction;

• impurities in oil, e.g. glycol, fuel.

4. Inadequate oil pressure

Serious deficiency of oil pressure for an extended period (above 8-10 seconds) apart of polishing and scorching the surfaces of bearings’ sleeves causes thermal discoloration. Insufficient oil pressure is the most dangerous form of irregular oil supply.

Possible reasons:

• bent, broken or clogged turbocharger’s lubricating line;

• failure of the oil pump;

• low level of oil in the oil sump;

• deficiency of lubrication due to extended operation on sharp slope.

5. Overheating

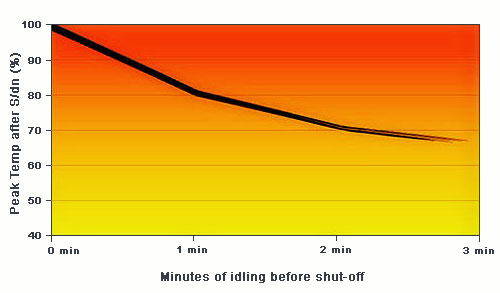

The high temperature passage from the turbocharger’s exhaust to the middle trunk causes burning of oil and corrosion of bearings. Deposit of coal (burned oil) is caused by excessive temperature of exhaust gases or by too soon turning off the engine after operation. It is advised to let the engine on neutral gear for some 2-3 minutes in order to cool the turbocharger down. The affected places are mainly the ring and grooves of turbine’s shaft and bearing. Burned oil residue also blocks the oil drain in the middle trunk. Deposited coal results in friction leading to bending and fracturing turbocharger’s parts.

Possible reasons:

• too early engine turn-off after operation;

• clogged or worn air filter;

• poor quality of engine oil;

• too infrequent replacement of engine oil;

• air and exhaust blow through;

• defective injectors;

• poorly fixed turbine trunk;

• defective lubricating system;

• defective oil draining system (faults in venting engine’s crankcase).