Oil leaks from turbocharger

Oil spills. In our daily work, this is one of the most common causes of a potential failure that our customers report to us for repair or purchase of a new component. What it comes from?

Sealing system in a turbine

To clarify the phenomenon of oil leaks, you must first mention the construction, specifically what it consists and how the turbo seal system works.

When the turbocharger lying on the workbench is filled with oil to block the flow of oil, one should not be surprised that the oil escapes from the middle body to both the suction side and the exhaust side. In order for the turbocharger to become airtight, turbulence and pressure in the exhaust and air side must be present. During proper operation of the system, these pressures are always higher than the oil pressure, which is about 1 bar after work on the bearings.

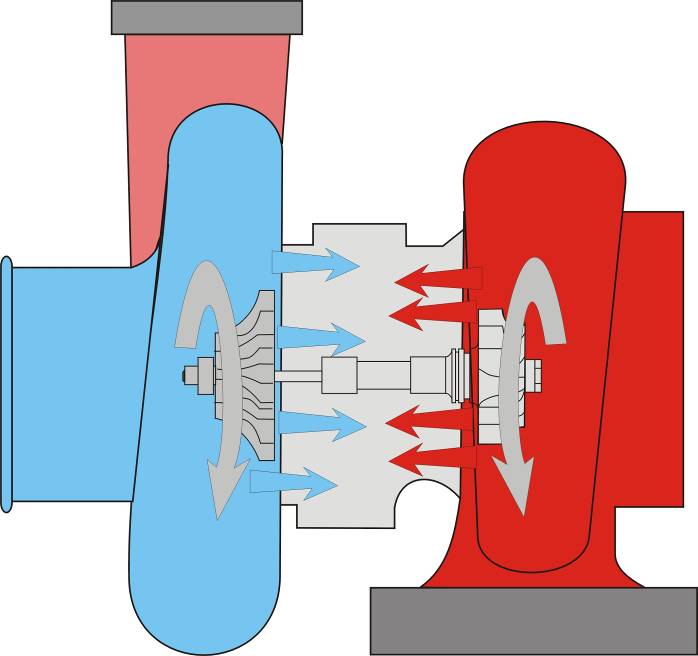

Fig.1

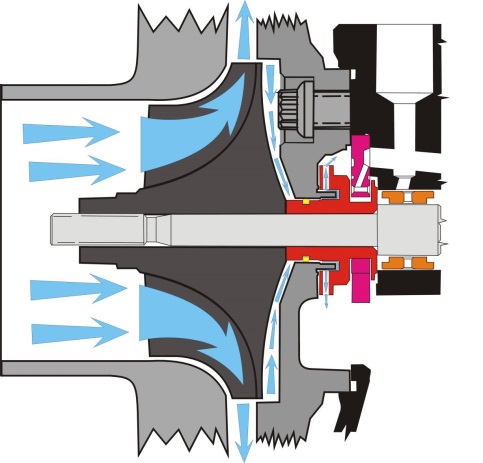

Due to the tremendous rotational speeds of up to 250,000 rpm and a temperature inside turbocharger, up to 1200 degrees Celsius on the exhaust side, typical O-rings can not be used for their construction. However the construction of the sealing system is quite simple. Both the cold side and the hot side works so called oil ejector with sealing ring. It is only during the rotation of the shaft that the centrifugal force rejects the oil outside to the special oil space that gravity flows into the oil pan. The mounted steel sealing ring pressure-tightened with exhaust gas further seals the system. Exactly the same phenomenon can be noticed on the air side, the difference is only in the construction of an oil dumpster which is built-in so-called back plate or a completely separate subassembly.

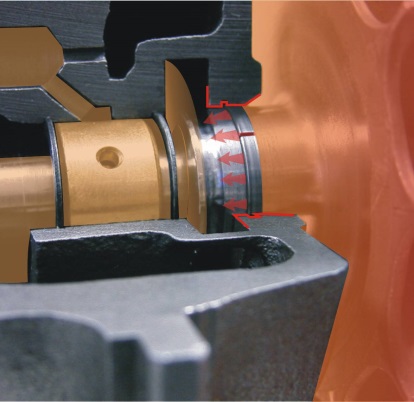

Fig.2 and 3

|  |

This is not always a failure.

The above technical solutions do not allow the oil to escape during proper operation and smooth operation, ie without a damaged turbine bearing system. Appearing oil spills are not in themselves a cause but a symptom indicating the possibility of a real cause of failure. The most common causes of oil leakage are not related to its damage and do not necessarily mean that it needs to be regenerated.

Abnormal running system of the crankcase venting system.

The turbo suction part not only sucks the air but also helps to relieve the crankcase. Often incorrectly separating the oil in the vapor results in oil on the compression wheel and then on the intercooler. However, it is not the turbocharger responsible for it.

Purging of engine.

It is generally known that the oil flows into the oil pan by gravity. In addition, the movement of the pistons causes the formation of a vacuum which facilitates its movement. Already a small increase in crankcase pressure blocks the free flow of oil from the turbine and causes it to leak, especially to the exhaust system of our car. The increase in crankcase pressure is influenced by: gas permeation through the valve rings, gas penetration through the valve guides, or gas penetration between the piston and the cylinder.

Other phenomena blocking the free flow of oil from the turbocharger

• Too high engine oil that blocks its free flow to the oil pan.

• Obstructed oil drain line, which can be bent or contaminated by old burnt oil, reducing its cross-section.

• Incorrectly selected gasket. The small diameter of the gasket effectively blocks the flow of oil, leading to oil leakage both at the flue gas side as well as compression.

Fig.4

Intrusions in the exhaust system

Having discussed the correct functioning of the sealing system, we have mentioned how important it is to have a proper pressure on the air side and exhaust gases, without which our turbo will not be airtight. Especially the latter is very important in the context of oil spills. Many of us often meet catalyst cut-off or solid particle filter services. Please note that removing any components from the exhaust system of your car results in a change in the exhaust gas pressure in the exhaust system, which most often results in turbocharger oil leaks, as these activities interfere with proper operation.

As can be seen not only the actual failure of the turbine is the cause of its leakage, but very often they are phenomena not associated with it. That is why it is important that the correct diagnosis be made by the mechanics. Finding the right cause of leaks will save the mechanic's time, but most of all the money spent on repairing or purchasing a new assembly.