Attention! Pirate

There are more and more fake (not genuine) spare parts on the market. We had the opportunity to compare such product of unknown origin – the fake turbocharger to the genuine product from our supplier.

Below please see the results and conclusions of the comparison.

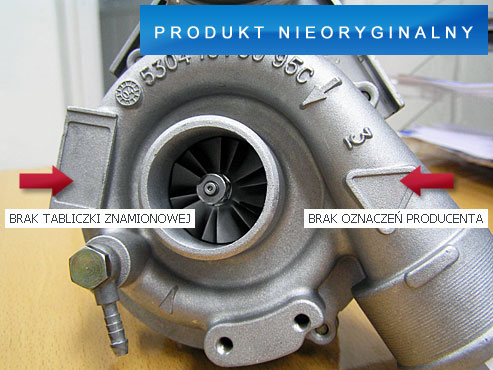

The researched turbocharger seemed suspicious from the first sight. It came from the VW Passat with the 1.8 turbo engine.

The turbocharger was devoid of any maker’s identification so it was quite obvious it was not a genuine part.

The below picture presents the researched turbocharger.

And the genuine product of the KKK company. The discrepancies may be seen with the naked eye.

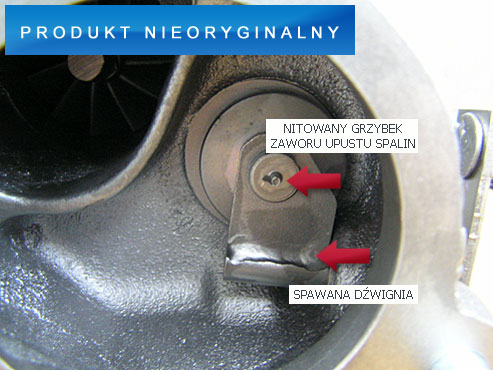

Another difference lies in the construction of the exhaust relief valve head.

In the fake turbocharger the construction of lever and head fastening/rigid, welded structure/ doesn’t provide the tightness of the valve in the device, leaving 2mm gap. This has a direct influence on the exhaust energy usage, decreasing the engine’s power output. In high temperature condition a rigid structure results in higher defect rate – cracking of welds and rivets.

Faked product.

Genuine KKK product.

During the comparative analysis of the turbocharger’s spinning assembly the substantially greater weight of the unit (charger’s wheels and turbine) was discovered in the fake unit. Increased weight of the spinning parts results in extended reaction time to changed working parameters (the reaction time after depressing the accelerator) causing the increased fuel consumption and decreased vehicle’s dynamics.

Asymmetrical oil draining hole from turbocharger.

The construction of oil drain as seen above may result in problems with gravitation draining of oil from turbine, leading in turn to leakages from turbine to exhaust and suction installations.

The turbochargers delivered for researched failed after two days of operation (the rotor’s shaft broke at the turbine wheel however no defects of bearing was discovered, meaning that faulty material was used for the rotor’s shaft).