Operation principles

Operation principles

Characteristic features:

1. Flaws

• large size and weight;

• necessity to use surge tanks;

• pollution of gas with oil used for lubricating the cylinder;

2. Advantages

• simple technical solution;

• ease of service;

• low repair costs.

Due to their construction we can differentiate the following types of compressors:

• single or multi cylinder units;

• upright or sideways oriented;

• cylinders in V-configuration;

• compressors with the energy saving assembly.

Principles of operation

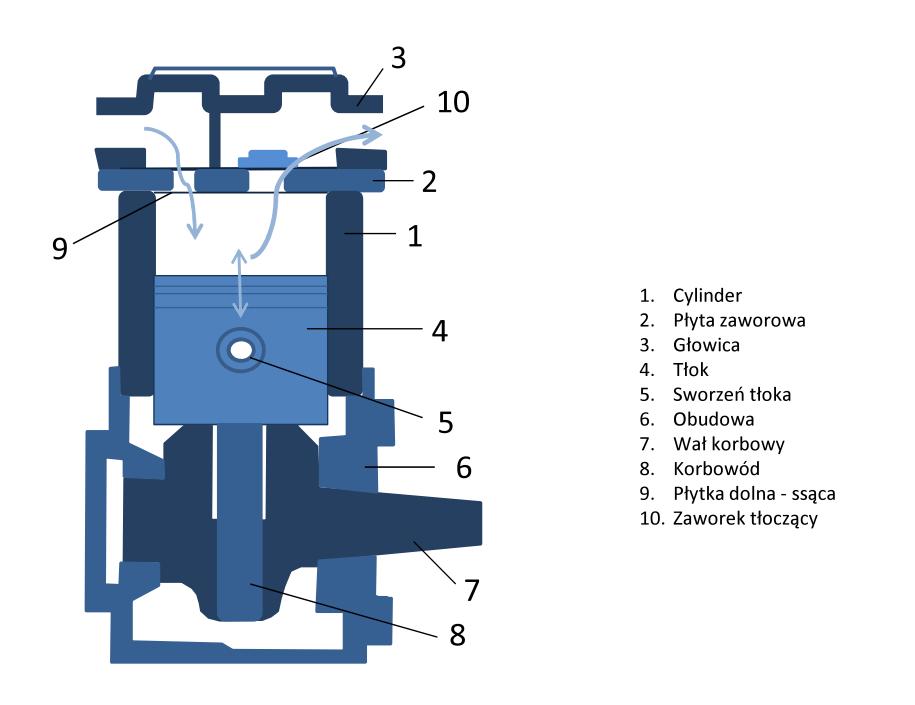

The basic parts of the piston air compressor are as follows:

• cylinder;

• head;

• crank assembly.

The detailed construction is shown below.

The operation of the compressor is realized through the reciprocating motion (to-and-fro) of the piston. When the piston moves downwards the negative pressure is generated in the cylinder. Due to pressure difference in the cylinder the suction valve opens, the lower plate opens downwards and the air from the suction manifold flows into the cylinder.

When the piston moves upwards the air in the cylinder is compressed. Due to pressure rise the suction valve shuts down, the lower plate fits tight the valve plate, preventing the return of air to the suction manifold of the engine. When the pressure rises above the pressing force, the bucket valve opens, upper plate opens and the air is forced by the piston from the cylinder into the pressure vessel.

State-of-art technical solutions used in air compressors include the energy saving installations. They are used in the modern compressors in order to:

• decrease fuel consumption (ecological reasons);

• improve the quality of air supplied to the vehicle’s pneumatic installation (shorter time of compressor’s effective operation lowers the temperature of pumped air, allowing for conditions for filtering out the moisture and oil).

Operation principles of energy saving assembly:

After the suitable pressure is reached in the vehicle’s pneumatic installation, from the specific valve the pneumatic impulse is sent to the energy saving assembly. This results in unsealing the suction chamber of compressor’s head and drop of pumping efficiency to a very small value. Power consumption is cut from over a dozen to just few kW.

WABCO compressors

WABCO – Belgian brand with over 140 years of tradition.

Westinghouse Air Brake Company (WABCO) was founded by George Westinghouse in 1869.

Among the wide range of their products there is a large group of compressors, which the most important features can be described by the four following groups.

C-COMPTM – Air compressors with energy-saving system.

It has a simple on/off system using the built-in clutch controlled with pneumatic signal. Draws power from the engine only in the pumping phase, while remaining totally disabled during the long phase of the discharge of the system. This reduces the compressor's energy demand and thus saving fuel.

D-COMPTM – Two-stage air compressors.

The new, revolutionary, two-stage compressor greatly reduces the problems of degradation and oxidation of oil in the compressed air. The use of new technologies in the automotive field has allowed the compression process divided into two operations separated with cooling process. The result is max. the air temperature at about 250 °C, giving a much better air quality and providing significant benefits in operating costs.

H-COMPTM – Air compressor with high efficiency.

This highly modular design of WWM (Wabco's Worldwide Modular) garnered global customers. Combinations of the compressor mounted and those in the global marketplace compressors offer the possibility to adapt to specific customer requirements. Today's design WWM compressors based on 85mm piston diameter. In response to growing customer demand for air compressor developed high performance (High Output), which is the piston diameter of 100mm. This increases the amount of air supplied. This proposal fills the gap between the 1-cylinder compressors with 85mm piston and 2-cylinder.

E-COMPTM – Air compressor driven by an electric motor.

This proposal provides an efficient solution for the new generation of vehicles with electric or hybrid systems. Hybrid engines are usually too small to allow the installation of a conventional compressor flange. Rugged, compact and modular design allows you to customize it for all types of vehicles. The most suitable displacement can be chosen from a series of WWM.

KNORR-BREMSE compressors.

KNORR-BREMSE is a German brand with over 100 years of tradition.

A wide range of products include air compressors for trucks. They are produced as a one-cylinder and 2-cylinder, flange-mounted direct drive and cantilever mounted with belt drive. Optionally, these compressors can be equipped with a power management system (ESS).

One of the latest innovations from Knorr-Bremse is the air compressor with energy-saving system that reduces operating costs associated with fuel and oil.

For smaller vehicles not equipped with air brake and passenger cars, Knorr-Bremse offers a two-stage, oil-free compressors to power the air suspension system or brake.